GLAMR LAB LAYOUT

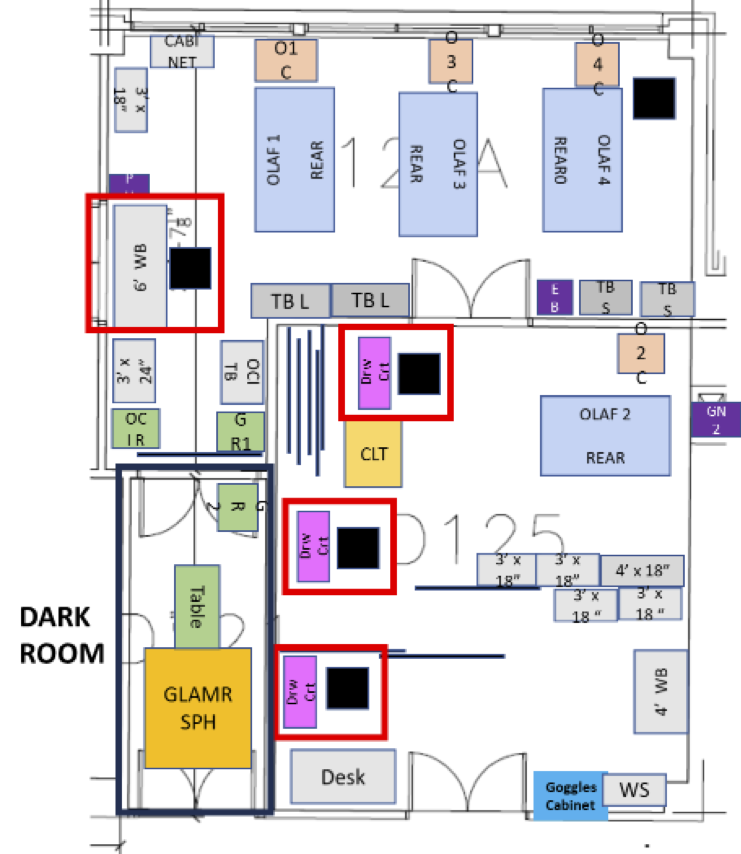

The drawing below shows a representative picture of the GLAMR lab layout. The actual layout may vary based on what lasers are installed in the lab. The black box identifies the dark room, which is where the calibration/characterization will take place. The red boxes indicate potential workstation areas for instrument personnel. The blue boxes labeled “OLAF#” are the tunable OPO lasers and eye protection is required when in the room while they are in use.

actual layout may vary based on what lasers are installed in the lab. The black box identifies the dark room, which is where the calibration/characterization will take place. The red boxes indicate potential workstation areas for instrument personnel. The blue boxes labeled “OLAF#” are the tunable OPO lasers and eye protection is required when in the room while they are in use.

GLAMR CALIBRATION ENVIRONMENT

- Integrating sphere with variable port sizes (8”, 10”, 12”)

- Note that this sphere does not get hot, so proximity to sphere is not a concern for instrumentation.

- Isolated dark room

- Lasers are fiber coupled to the sphere from adjacent rooms

- Temperature range: 67-75 deg F (19.5-24 deg C) – no lab control

- Humidity range: 15-70% - no lab control

- Height adjustable cart with at 2’ x 4’ breadboard for instrument mounting, pictured at right, in front of sphere

- 110 V, 208 V single phase and 208 V 3-phase power available (power cords are required to be provided by the instrument team)

- Chiller available to provide cooling water

- 20 psi nominal pressure (adjustable)

- ~1.3 GPM @ 20 psi

- 3/8” ID hoses

- Gaseous N2 available for instrument purging (10 psi, 1 scfm flow rate)

- Dew point <-20 deg C

- ¼” Swagelok connection

- Masterclock time server available for time synchronization

- Cameras monitor the dark room during calibration efforts

- Clean environment (NOT a clean room)

LOGISTICS

- For time synchronization with our time server, your instrument must connect to GLAMR’s network.

- Time synchronization is essential for an efficient GLAMR test.

- >25 ft cables required to connect instrument in the dark room to the available workspace/monitoring locations

- Multiple workspaces are available for multiple personnel

- If you use the GLAMR chiller, similar length tubing must be provided.

- Results with wireless connections have been poor.

- External internet access is available (requires advance notice and advance setup)

- Tools and facilities available for basic repairs

- Two shift operation is possible depending on the test needs

- Can accommodate standard gas cylinders as long as instrument team provides regulator and their own plumbing

- Real-time telemetry is available via a CCSDS server for use by the instrument team or via a data server for viewing on a monitor.

- Limited capability lab computers are available for use (no internet access)

- Building has a standard loading dock or a garage bay for loading/unloading hardware.